Micro Communications (MCi), A Microwave Techniques Company, offers various capabilities for RF engineering, microwave component and system design, precision broadcast manufacturing and RF test lab capabilities.

Micro Communications is part of the Microwave Techniques group, which occupies 90,000 feet of manufacturing space between Nashua, New Hampshire and Gorham, Maine USA. The group operates three state-of-the-art precision machine shops tailored to the accurate needs of RF components fabrication.

Manufacturing Capabilities

MCi specializes in prototype production and small-to-medium quality runs, our manufacturing capabilities include:

- Large size CNC and conventional machining

- Full quality control and quality assurance nondestructive testing

- Milling

- Drilling, bending and punching

- Plasma cutting and burning

- Certified welding

- SMAW

- FCAW

- GMAW

- GTAW

- SAW

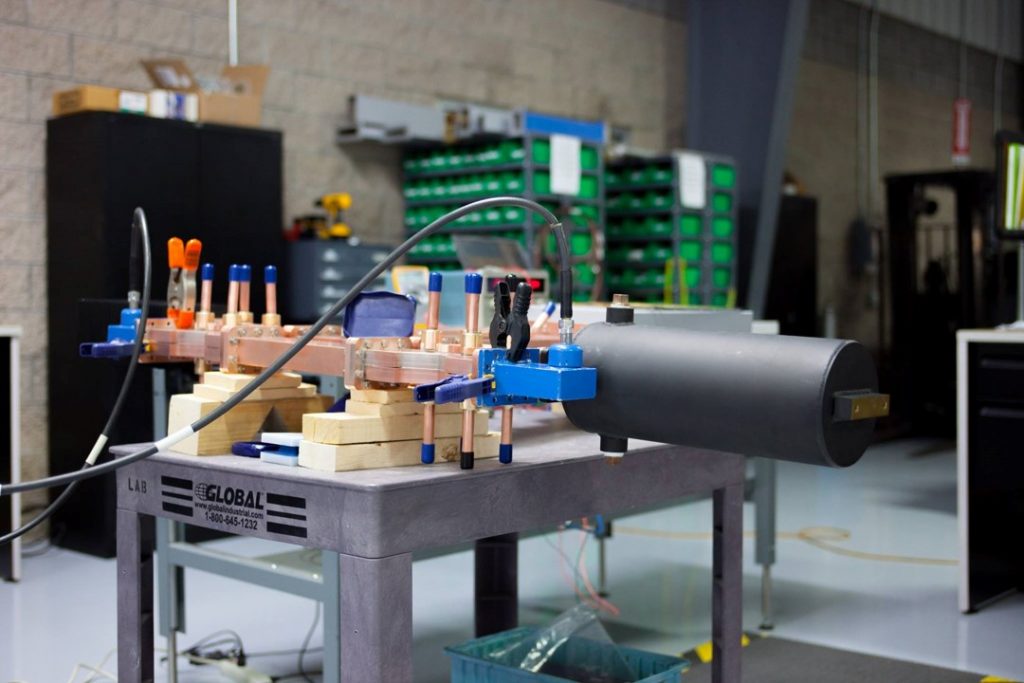

Testing & RF Lab Capabilities

Micro Communications Testing & RF Lab has a full range of testing and measurement capabilities to characterize and test the exceptional performance of the microwave products we manufacture. MCi has the capability to measure components up to 40 GHz. All of our electrical test and RF assembly equipment is fully ISO accredited and certified. As a commitment to quality and excellence, we maintain ISO 9001 and AS 9100 certification.

Our advanced testing and RF lab capabilities include:

• Low-level RF measurements 3kHz to 40 GHz

• DC high-pot testing to 80kV

• High pressure testing to 60 psig with air

• High pressure testing to 250 psig with hydrostatic

• Gas leak rate measurements down to 0.05 cc/min @ 1.0 psig

• Helium (He) “sniffer” leak testing

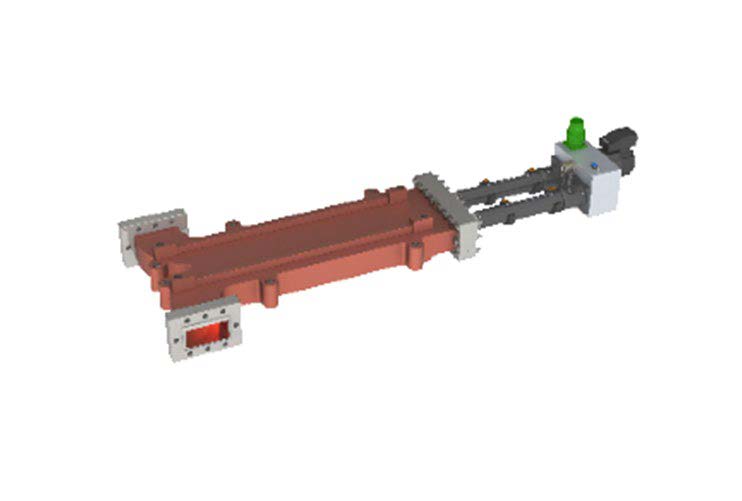

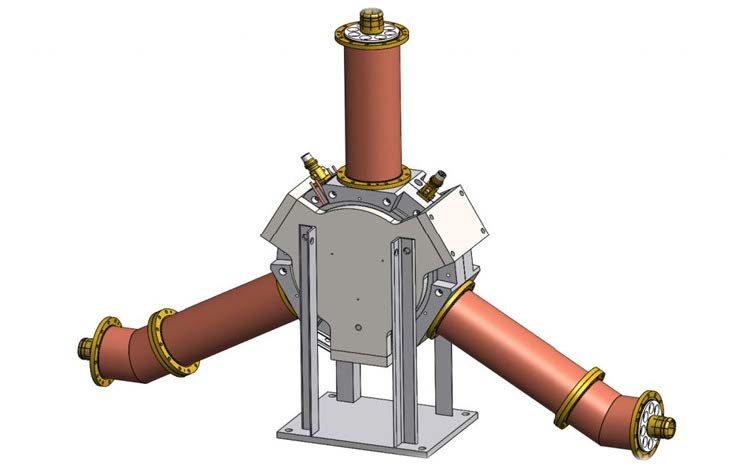

Engineering & Design Capabilities

- CST Microwave Studio for RF Simulation and Multipactor Analysis

- Ansys Electronics Desktop (HFSS)

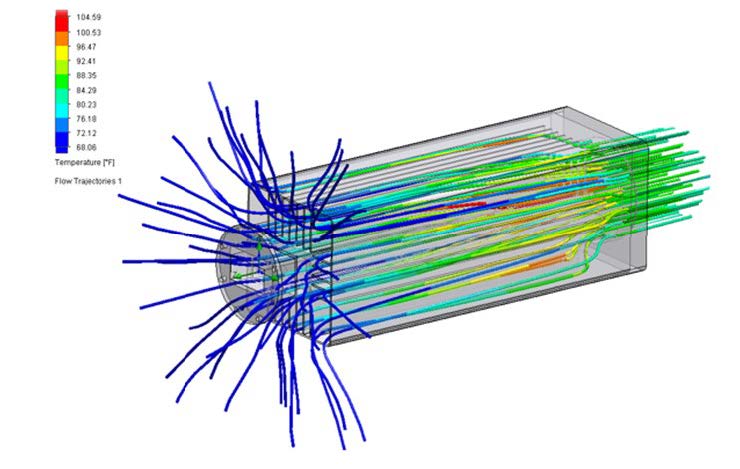

- SolidWorks Flow Simulation for thermal analysis

- SolidWorks Simulation for mechanical, cyclical and pressure analysis

- Full suite of Vector Network Analyzers (VNA)

- PC DMIS with a 3D Romer Arm

MCi: A Microwave Techniques Company

Microwave Techniques, LLC is a global leader in high-power microwave solutions. The group includes Micro Communications (MCi), Ferrite Microwave Technologies, MEGA Industries and the FXR dummy load product line. The group manufactures the widest line of high power RF components and microwave systems, supporting waveguide sizes WR28 to WR2300, supporting 50 MHz to 50 GHz that handle power levels ranging from 5 W to well over 50 MW.

To learn more about Micro Communications, A Microwave Techniques Company, or to discuss your application – please contact sales@microwavetechniques.com